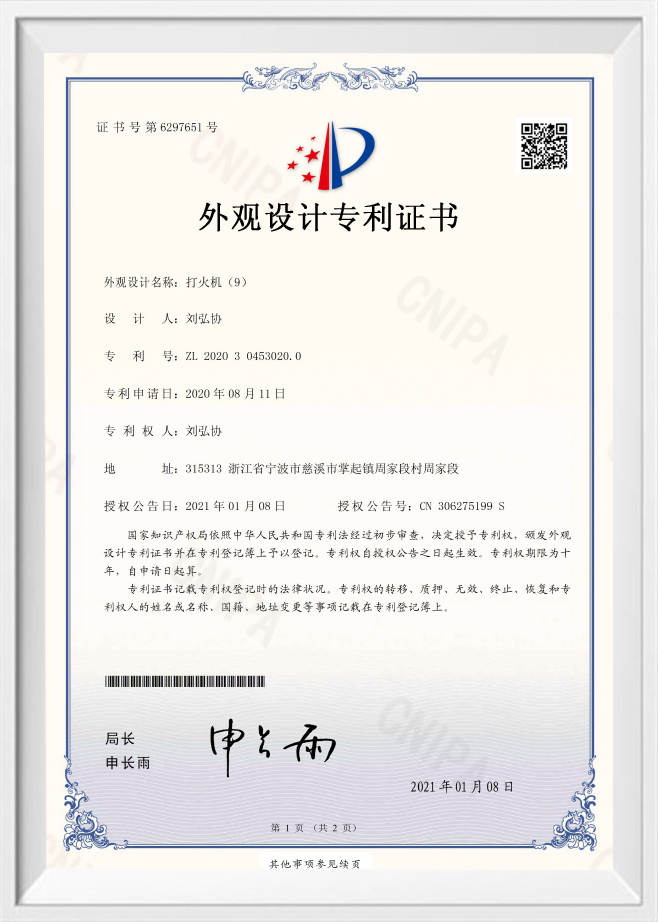

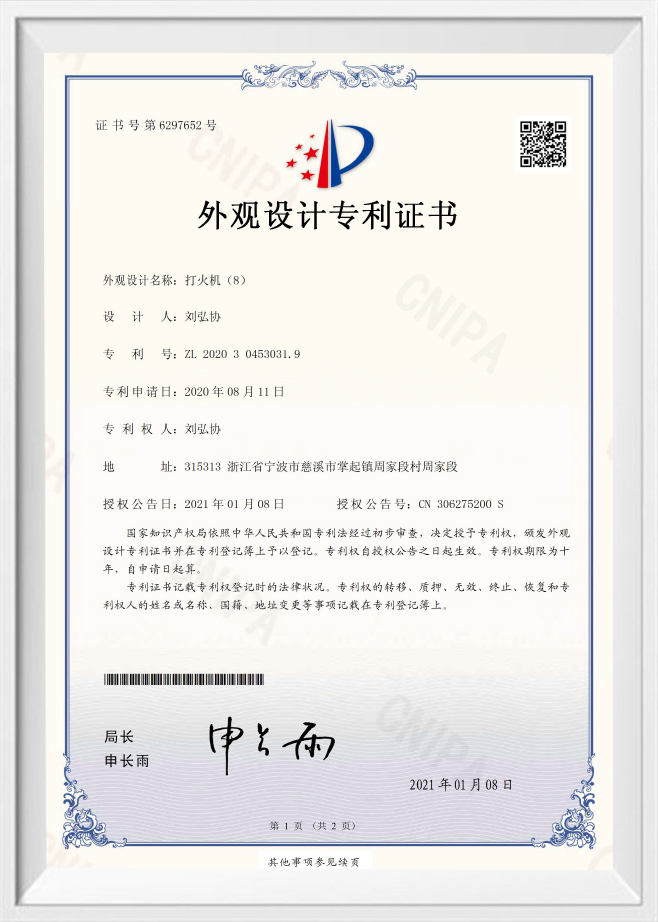

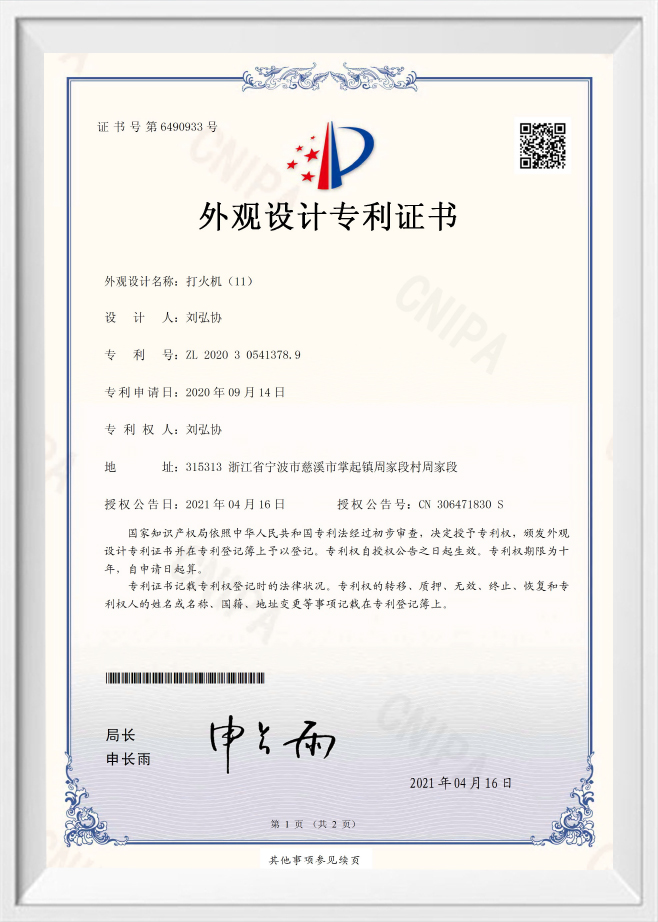

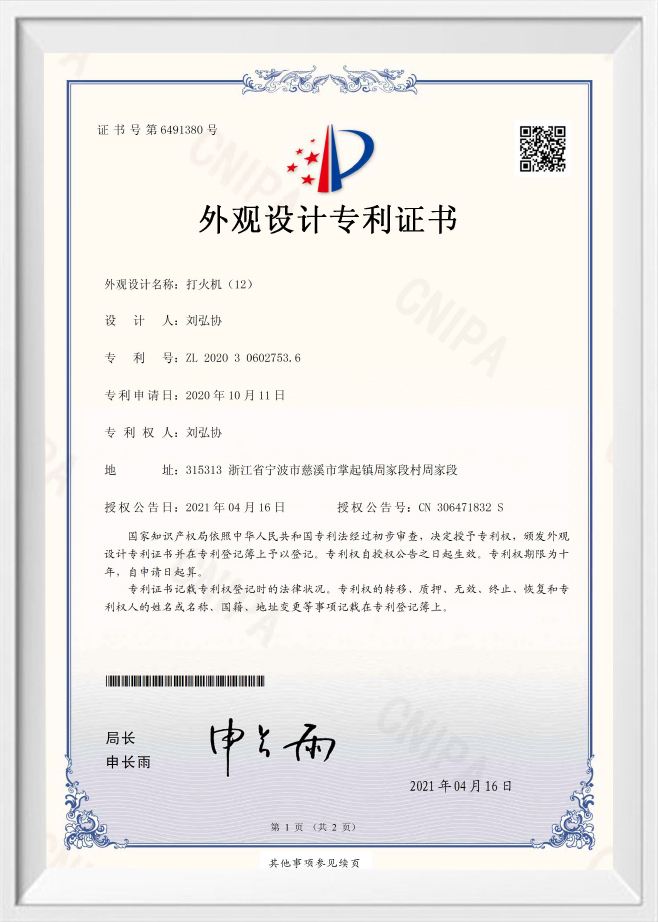

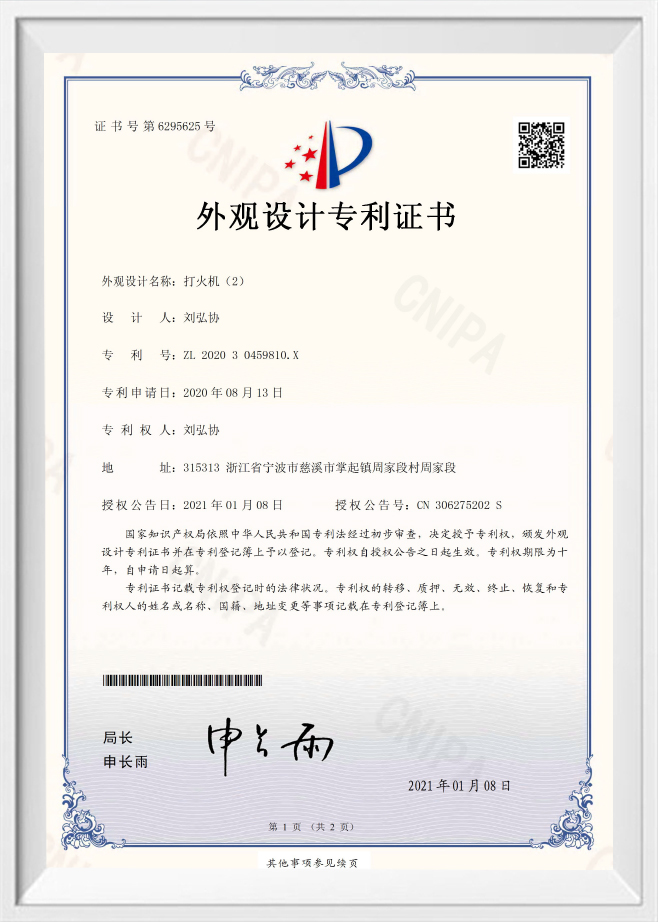

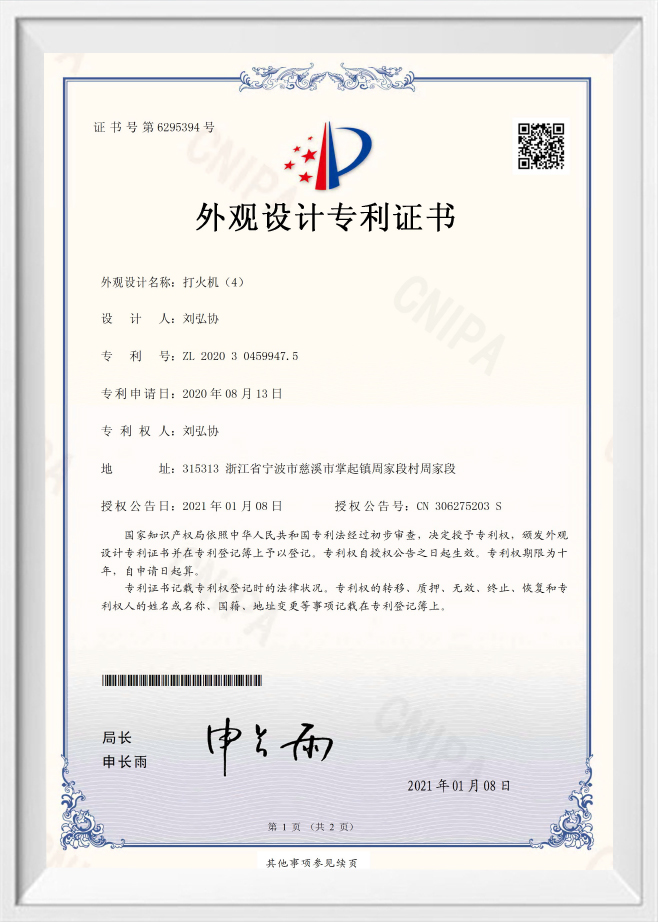

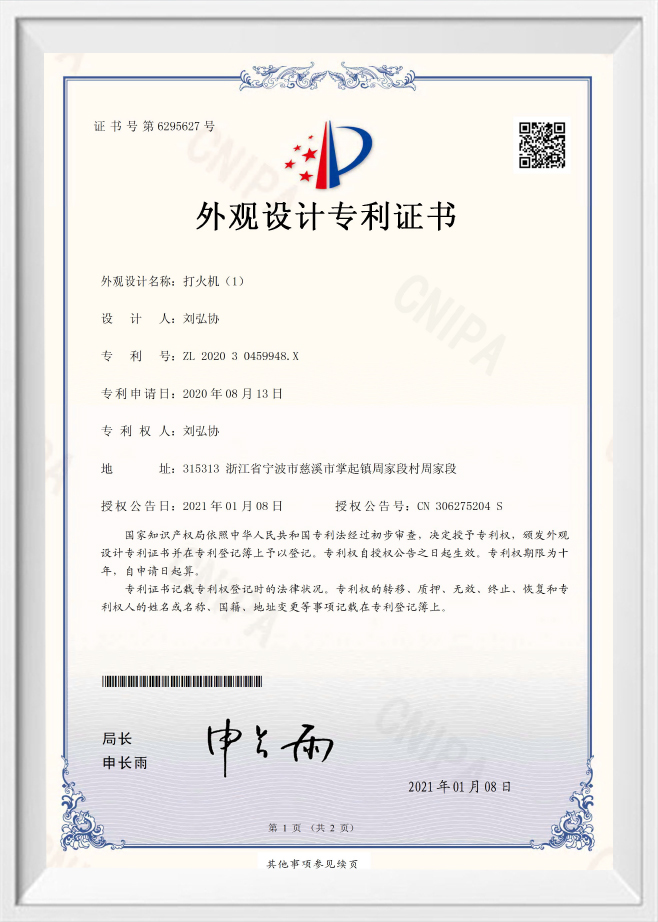

How does the Iron Shell Resistance to Fall Lighter’s iron alloy shell set a new benchmark for drop- and corrosion-resistant lighters?

The iron alloy shell is a key component of the Iron Shell Resistance to Fall Lighter’s design, and this carefully crafted structure is the cornerstone of its durability. This alloy is a blend of iron and other carefully selected metals designed to provide the best strength-to-weight ratio, corrosion resistance, and impact toughness. The resulting shell is lightweight yet strong, capable of absorbing the impact of a fall from considerable heights without compromising its integrity or functionality.

The choice of the iron alloy was not random, but the result of extensive research and testing. The specific composition of the alloy was tailored to the unique needs of the lighter, including resistance to high and low temperatures, as well as moisture, humidity, and even salt spray in coastal environments.

The Iron Shell Resistance to Fall Lighter’s drop resistance does not rely solely on the strength of its shell, but is the result of multiple design elements working in harmony. The location of internal components within the shell is carefully designed and fixed to minimize the risk of damage upon impact. Additionally, shock-absorbing mechanisms such as damping materials or carefully placed reinforcement ribs can be incorporated to further dissipate the energy of a fall.

The durability of the Iron Shell Resistance to Fall Lighter is not limited to drop resistance, as it is also designed to operate reliably in different environmental conditions. Its iron alloy shell is inherently resistant to corrosion and high temperature fluctuations, providing a solid barrier to protect the internal components from harsh external factors. The components of the lighter are carefully selected and designed to withstand high temperatures without degradation or failure. This ensures that the Iron Shell Resistance to Fall Lighter can be safely used in hot environments, such as deserts or campfires, without worrying about failure. Equally impressive is the lighter's ability to operate reliably in low temperatures. Special attention is paid to the viscosity of the fuel and the ignition mechanism of the lighter to ensure fast and continuous ignition even in freezing conditions. To prevent moisture intrusion, the Iron Shell Resistance to Fall Lighter employs seals and gaskets at key connections. In addition, the shell may be treated with an anti-corrosion coating to further protect against moisture and salt spray, ensuring that the lighter will function properly even in humid or coastal environments. For users who frequently travel to coastal areas, the Iron Shell Resistance to Fall Lighter's salt spray resistance is essential. After rigorous salt spray testing, the lighter's casing and coating have been proven to resist the corrosive effects of sea salt and moisture, ensuring reliable functioning in the most challenging marine environments.

English

English русский

русский Español

Español عربى

عربى