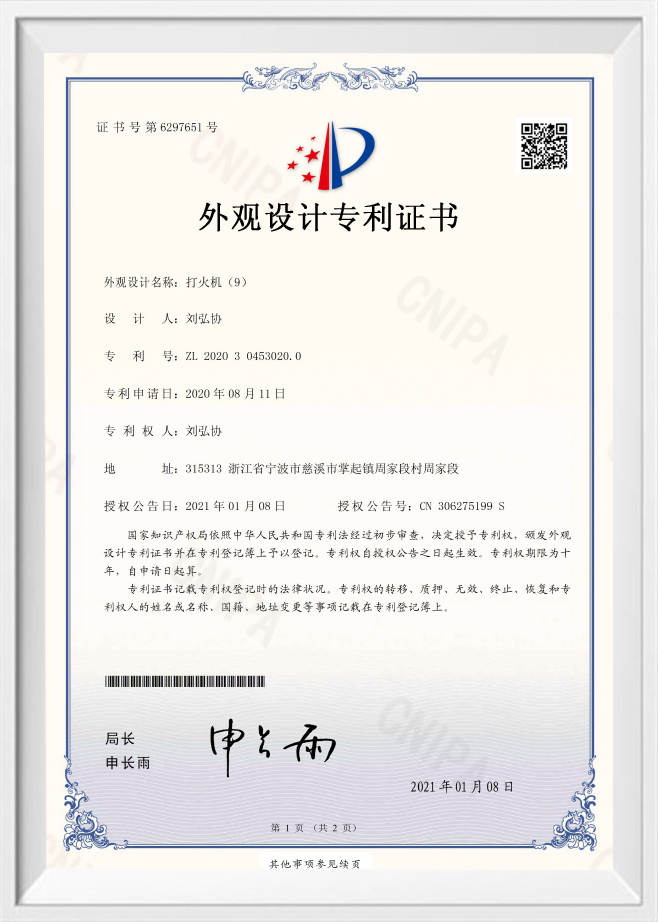

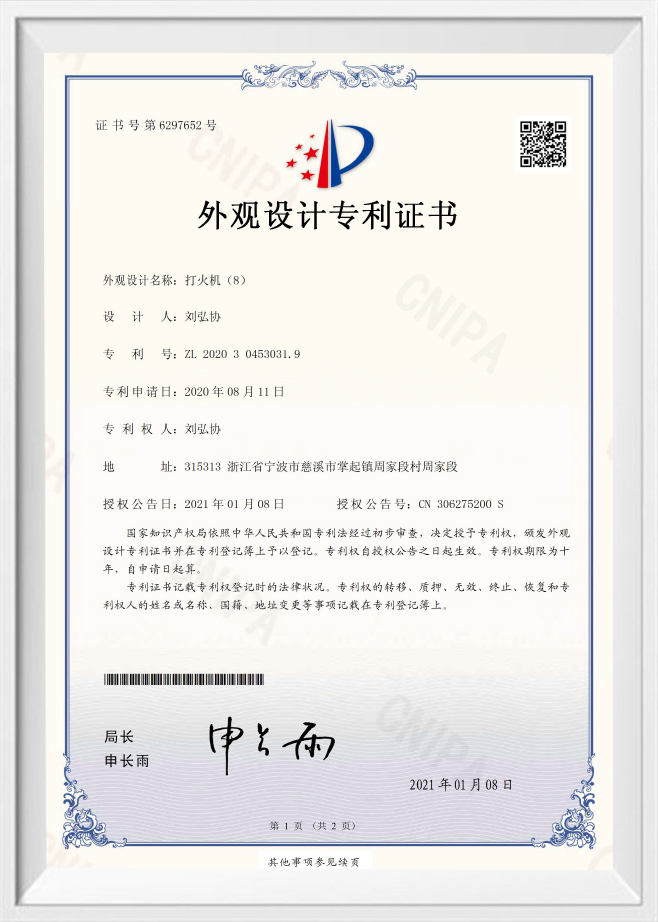

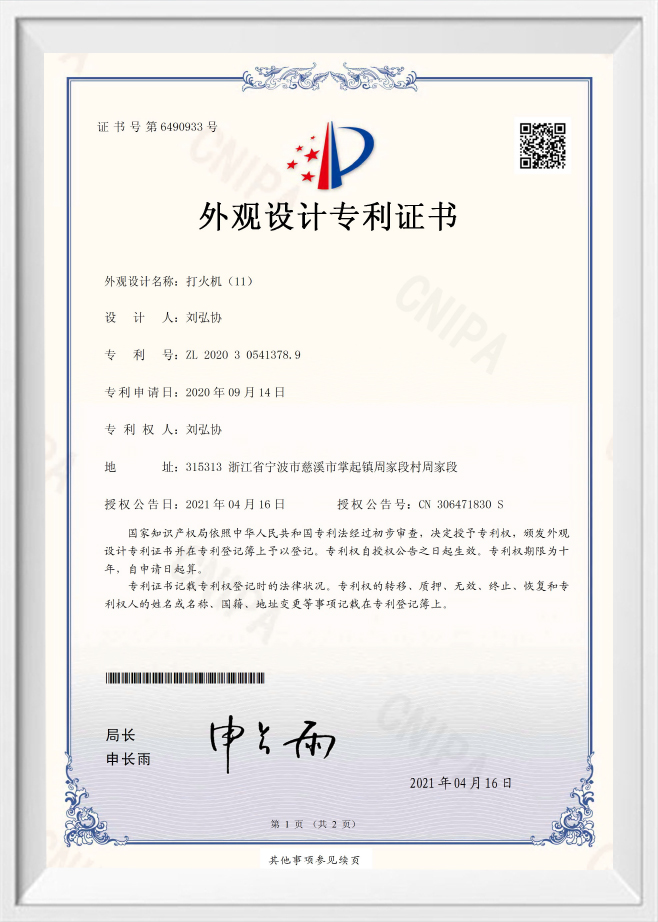

Portable Iron Shell Lighter, is it really durable and corrosion-resistant in high-altitude environments?

The iron shell design of Portable Iron Shell Lighter not only gives it a sturdy and durable appearance, but also protects the delicate internal ignition mechanism to a certain extent. However, the unique natural environment in high-altitude areas poses a double challenge to this lighter. The air pressure in high-altitude areas gradually decreases with the increase in altitude, which directly affects the evaporation rate of the fuel inside the lighter. In a low-pressure environment, the evaporation rate of the fuel slows down, which may cause ignition difficulties or unstable flames. At the same time, the low temperature environment also exacerbates this problem. The fluidity of the fuel deteriorates at low temperatures, further affecting the reliability of ignition. In addition, low temperatures may also make the coating on the surface of the iron shell brittle and accelerate the aging process.

The climatic conditions in high-altitude areas are complex and changeable, and may be accompanied by strong ultraviolet radiation, high humidity, pH changes and other factors. These environmental factors may pose a threat to the corrosion resistance of the iron shell. Ultraviolet radiation accelerates the aging of the coating, causing the shell to lose protection; high humidity environments may cause electrochemical corrosion and accelerate the rusting process of the iron shell; and changes in pH may directly corrode the metal surface, causing irreversible damage.

In order to cope with the challenges in high-altitude environments, manufacturers and consumers need to adopt a series of professional strategies to improve the durability and corrosion resistance of Portable Iron Shell Lighter.

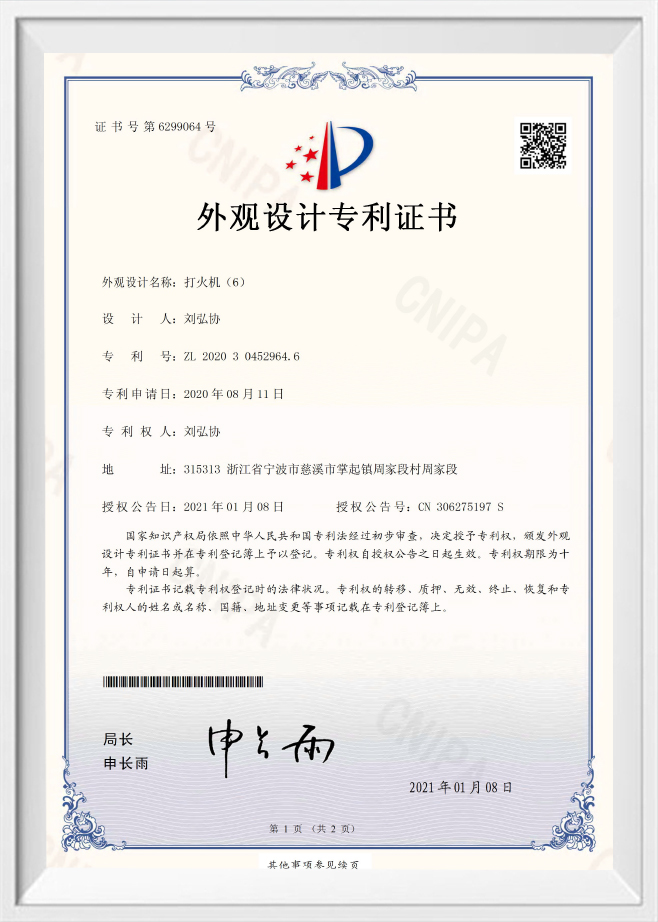

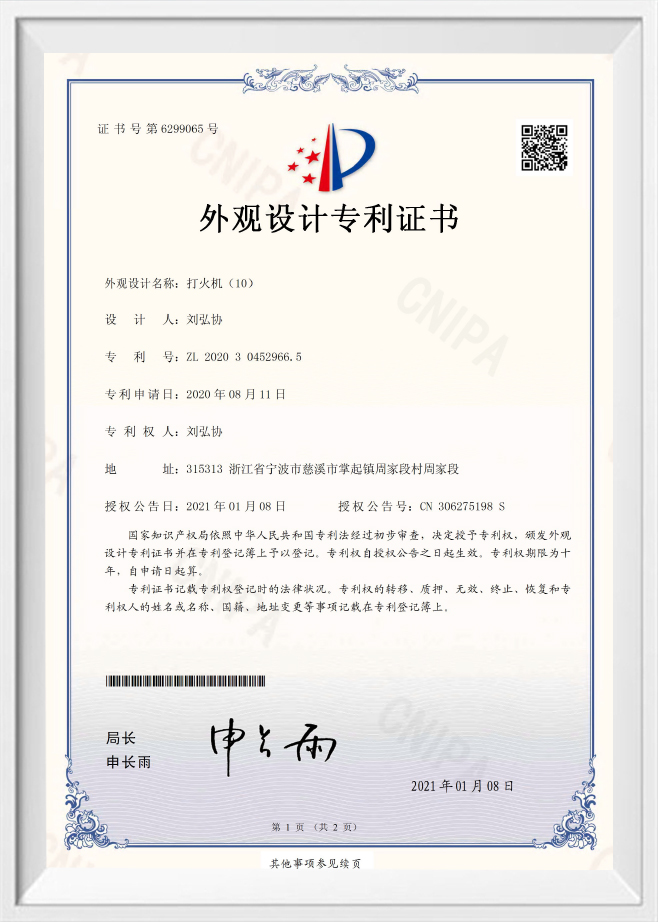

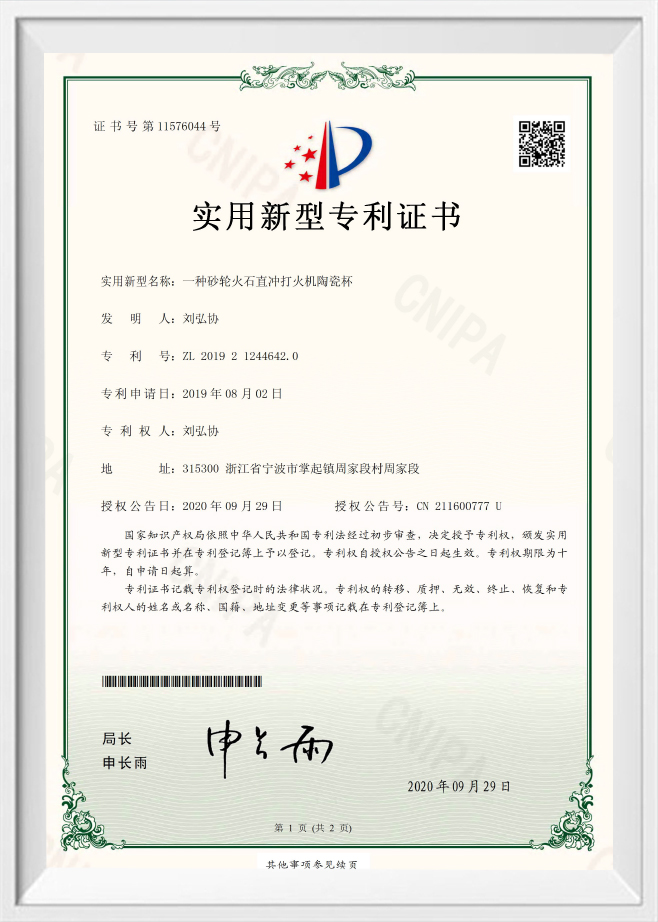

Advanced anti-corrosion treatment technologies, such as multi-layer nano-ceramic coatings or special alloying treatments, are used to enhance the corrosion resistance of the iron shell. These technologies can not only effectively resist the erosion of ultraviolet radiation and high humidity environments, but also maintain stable performance in environments with pH changes; design and optimize the fuel system for changes in air pressure in high-altitude areas. By adjusting the fuel formula and internal structure design, it is ensured that the fuel can evaporate stably and ignite smoothly under different air pressure conditions. At the same time, an automatic adjustment mechanism is introduced to cope with the impact of air pressure fluctuations on the ignition effect; a detailed high-altitude use guide is provided, including ignition techniques, fuel selection and replacement methods, daily maintenance steps, etc. These guidelines will help consumers better understand and use Portable Iron Shell Lighter to extend its service life and improve its use effect.

Before using in high altitude areas, carefully study and select the appropriate fuel type. Give priority to fuels that can adapt to low pressure and low temperature environments to ensure the stability and reliability of ignition; try to avoid exposing Portable Iron Shell Lighter to humid and corrosive environments. When using in rainy and snowy weather or saline-alkali areas, appropriate protective measures should be taken, such as using waterproof bags or wrappings to reduce the erosion of the external environment on the lighter; perform professional maintenance regularly according to the manufacturer's recommendations. This includes cleaning the outer shell, checking whether the coating is intact, replacing worn parts, etc. Professional maintenance can promptly detect and repair potential problems and ensure the continued stable operation of Portable Iron Shell Lighter in high altitude environments.

English

English русский

русский Español

Español عربى

عربى